— Whole Wheat Chakki / Multi Grain Atta Chakki Plant Setup Cost

Looking to establish a Whole Wheat Chakki Atta Plant? Setup costs can range approximately between ₹25 Lakhs to ₹1.5 Crores depending on capacity, automation, and machinery configuration. These plants are available in semi-automatic and fully automatic variants to suit your production requirements.

Types of Whole Wheat Chakki / Multi Grain Atta Plants:

a) Small Plants (1–2 TPH)

-

Ideal for small businesses and startups.

-

Requires around 2,500 sq. ft. of space.

-

Power consumption: approx. 120–270 kW.

-

Compact setup with efficient processing capabilities.

b) Medium Plants (2–6 TPH)

-

Suitable for mid-size production units.

-

Requires approx. 6,000 sq. ft. of area.

-

Energy use: around 270–600 kW.

-

High efficiency and scalable design.

c) Large Plants (6–10 TPH)

-

Perfect for industrial-scale flour milling operations.

-

Needs approx. 8,000 sq. ft. of land.

-

Consumes about 600–850 kW of power.

-

Fully automatic with no human intervention during production.

Key Specifications & Features of Whole Wheat Chakki / Multi Grain Atta Plant Machinery:

-

Operational Efficiency: Up to 99%

-

Maintenance Requirements: Low – Includes routine conveyor cleaning and stone chipping at every 250 hours

-

Automation Level: From semi to fully automatic

-

Noise Level: Maintained within industrial norms

-

Project Type: Greenfield – No waste generation

Click “Get Quote” for a customized cost estimate based on your business needs.

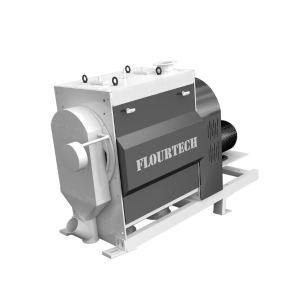

— Machines Included in Atta Chakki Plant Complete Setup!