Energy Food Plant

Flourtech’s machines and Energy Food Plant have been designed and developed with the objective of enabling processing of a variety of grains. Moreover, the Flourtech’s innovative technology and easy-to-use features allow machines to rapidly adjust to suit different applications as well as specific requirements.

Production capacity- 25 to 240 tons per day

Cooler– This is used to reduce the temperature of material. As an eminent manufacturer and exporter in this domain, we are providing our clients excellent quality cooler that is used to reduce temperature. Manufactured using quality approved components under the guidance of our seasoned professionals, this sifter is made available in various technical specifications. This cooler is tested by our quality inspectors as per the strict quality standards. The offered machine can be availed from us at industry leading prices.

Mixing Line– This machine is used to mix two or more materials. You can inspect your product, and make changes if necessary. The basic substrate and aggregates are mixed (rapidly or vigorously as desired) in a specially designed horizontal mixing Optionally, after the mixing process, an amount of water can be added to the finished product.

Sugar Grinder– Sugar Grinder is used to grind the sugar. We are a trusted organization, successfully engaged in manufacturing, exporting and supplying superior grade Sugar Grinder. This is manufactured under the guidance of our adroit professionals using optimum quality components with the aid of progressive techniques.

Roaster Cum Blendor– This is used to blend and roast the material. We are involved in providing superb quality range of Blender Cum Roaster that is available in different specification. The offered product is manufactured using the optimum quality raw material and modern technology in synchronization with the set industry standards.

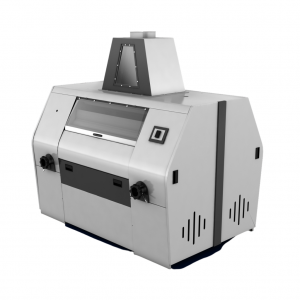

Horizontal Roller Mill– A horizontal roller mill machine can be used for grinding of different variety of wheat, barley, malt and any other grinding applications. Horizontal configuration with direct pickup with feed roll engaged and disengaged. Uniform distribution of the product to grinding rolls with the help of feeding roll at constant rate. Industrial automatic roller mill machine grinding operation takes place with series of roller mill. Grinding capacity and quality of ground material depends on number of roller mill used in the milling plant.

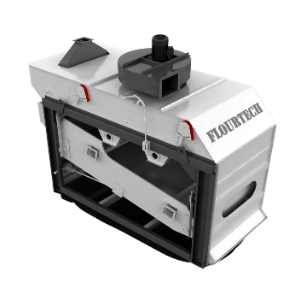

Plan Sifter– As an eminent manufacturer and exporter in this domain, we are providing our clients excellent quality Plan Sifter that is used to separate small granules & powder impurities with the help of various sizes of sieves. Manufactured using quality approved components under the guidance of our seasoned professionals, this sifter is made available in various technical specifications. This Plan Flour Sifter is tested by our quality inspectors as per the strict quality standrads. The offered machine can be availed from us at industry leading prices.

Reverse Air Jet Filter– With firm commitment to quality, our organization is engrossed in offering a wide range of Reverse Jet Filter. The provided filter is used to provide high quality filtration of the conveying air, providing continuous operation. The offered filter is manufactured with the use of superior quality components and highly advanced techniques as per international quality standards. In addition, our clients can purchase this Reverse Jet Filter at the most competitive prices from us.

Reel machine– To remove the various impurities. Also used for grading purpose. We are manufacturing machine with latest and sophisticated technology. This is a sieve separator widely supplied to flour and dall milling industry. Used for pre-cleaning and grading and separating jute twine cutting rugs, the Reel Machine separates out big size materials like chalk, husk and stones through sieve. Our machines can be available by customers in different capacities at cost effective price.

Destoner Machine– Appreciated for its high performance and less maintenance, the provided Destoner Machine is demanded across the globe. This machine is widely demanded in various food processing plants for separating stone, dust and other foreign particles from food grains. The offered Destoner Machine is manufactured using premium grade components with the aid of sophisticated techniques.

Pre Cleaner– Being a quality devoted entity, we are betrothed in manufacturing, exporting and supplying pristine quality Pre Cleaner Machine. With the aid of latest techniques and pristine grade components, the provided machine is manufactured by ingenious professionals. The offered machine is widely used for removing dust and impurities from rice, grains and seeds. Our valuable clients can avail this Pre Cleaner Machinefrom us at market leading prices.

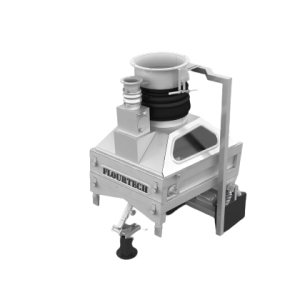

Gravity Selector cum Destoner– Gravity Selector Cum Destoneris used to remove stones from the material. This machine is used in milling plants for removing stones and other impurities for food grains and pulses. Our offered machine is manufactured using basic components and ultra-modern techniques in adherence to set industry standards.We have used latest technology and trained engineers to developed the machines.

Vibro Separator- We are a well-recognized manufacturer and exporter of Vibro Separator that includes a vertical type special motor which facilitates three dimensional motions which are circular, composed and elliptic in vertical, horizontal & inclination faces. This separator is designed and manufactured using premium grade raw material at our sophisticated manufacturing unit by our experts. The offered Vibro Sieve Separator is available in various technical specifications according to the requirements of our clients at industry leading price.

Aspiration Channel– Being a leading firm in this industry, we are engaged in offering a high quality range of Aspiration Channel. The provided channel is manufactured using optimum quality components as per set quality standards with the aid of ultra-modern techniques by our ingenious professionals. This channel is widely used in grain cleaning applications for separating lighter particles from granular products. Apart from this, our clients can avail the offered Aspiration Channel at competitive prices from us.

Micro Feeder– The micro-feederis is used to mix the additives in the material. The micro-feeder MZMC is a module designed for high-precision volumetric proportioning of micro-ingredients. Its throughput rate can be selected across a very wide range. For accurate control of the gravimetric addition of micro-ingredients in a continuous product stream, Bühler offers its micro-differential proportioning scale MSDC. Operating in the batch mode, this differential-weight scale based on the “single-screw” principle weighs small batches defined by the product recipe.

Centrifugal Fan– We are an outstanding entity, betrothed in manufacturing, exporting and supplying top grade Centrifugal Fan. This fan is manufactured by a team of our skilled professionals using supreme quality components at our sophisticated premises. Finding its application in various industries, the provided fan is widely used for moving air or other gases. Apart from this, the offered Centrifugal Fan can be bought by our valued patrons at market leading prices from us.

Airlock– We are a trusted organization, successfully engaged in manufacturing, exporting and supplying superior grade Industrial Airlock. This airlock is manufactured under the guidance of our adroit professionals using optimum quality components with the aid of progressive techniques. The provided airlock is used to control the flow of discharged material from a dust collector by maintaining an air seal. Apart from this, the offered Industrial Airlock can be bought from us at marginal prices.

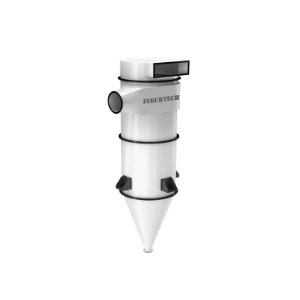

Cyclone– Being a customer oriented organization, we are deeply engaged in manufacturing, exporting and supplying a wide array of Industrial Cyclone. This cyclone is manufactured using optimum quality components by dedicated professionals at our modern premises. The provided cyclone is used in kitchen ventilation for separating the grease from the exhausted air in extraction hoods. In addition to this, the offered Industrial Cyclone can be bought from us at competitive prices.

Bin Discharger– It is fixed below the Bin to discharge the material from it. Individually engineered for each application, the unique design of Bin Discharger allows easy installation with the ruggedness to stay on-line. The Bin Discharger’s simple, compact design incorporates all of the important features customers have come to expect a leak proof molded sleeve, heavy duty suspension system and long life vibrator.