Pulse Processing Plant

Pulses like yellow peas, toor dal, black gram, chickpeas, horse gram etc, occupy an important place in human nutrition owing to its high protein content in comparison to cereal grains, which is why Flourtech’s Pulse Processing Plant have been designed to process pulses in a dust-free, pollution-free manner that retains its proteins and natural shine to provide customers with the desired results.

Production capacity- 25 to 250 tons per day

Fatka Machine– This machine is used to separate the cover of pulse. We are engaged in offering a wide range of Fatka Machine to our clients. The offered range of product is made from high grade quality raw material to meet the international quality standard.

Dehuller– We are instrumental in manufacturing, exporting and supplying an excellent quality array of Impact Dehuller for catering the various needs of our clients. This dehuller is manufactured using quality tested raw materials by a team of our adroit professionals with the implications of contemporary techniques. Owing to its impurity material separation capacity, it is used for hulling of sunflower seeds and oats for further separation of hulls. Moreover, this Impact Dehuller can be purchased at competitive prices.

Dal Polishing Machine– This machine is used for polishing pulses. They are used in various pulses mills for post-treatment and obtaining polishing. It is operated by a motor and the hopper is mounted at one end. The roller with lather rotates inside a screen. Passing through the screen dust get removed and the pulses which are polished pulses out of the outlet which is at the other end of the machine. Our machines are suitable to be used for polishing several type of pulses, grains and different type of crops. Furthermore, these products are equipped with advanced techniques to provide a shiny and silky finish to grains, pulses and rices.

Dal Splitter– A Dal Splitter machine is used to obtain cracking and scratching of clean pulses passing through it. For loosening the husk to facilitate the subsequent oil penetration this is required. Gradually the clearance between the emery roller and cage (housing) is narrowed from inlet to outlet. Cracking and scratching of husk takes place mainly by friction between pulses and emery as the material is passed through the narrowing clearance. During the operation some of the pulses are de husked and split which are separated by sieving.

Vibro Separator– We are a well-recognized manufacturer and exporter of Vibro Separator that includes a vertical type special motor which facilitates three dimensional motions which are circular, composed and elliptic in vertical, horizontal & inclinational faces. This separator is designed and manufactured using premium grade raw material at our sophisticated manufacturing unit by our experts. The offered Vibro Sieve Separator is available in various technical specifications according to the requirements of our clients at industry leading price.

Drum Sieve– Being an eminent organization in the industry, we are engaged in manufacturing, exporting and supplying a premium quality range of Drum Sieve. With the aid of latest techniques and pristine grade components, the provided sieve is manufactured by a team of our ingenious professionals. The offered sieve is widely used for sieving grains like rice, wheat, maize grit, pulses and many others. Our valuable clients can avail this Drum Sieve from us at market leading prices.

Rotary Separator– Established in the year 1988, we have achieved a position as a reputed manufacturer and exporter of superior quality Rotary Separator. It is used for the separation of light voluminous useless particles from the extracted air. Offered separator is manufactured as per the defined global industry standards by our seasoned professionals by making use of excellent quality raw material. We offer this Rotary Grain Separator in a variety of technical specifications to fulfill the client’s™ specific demands.

Gravity Selector cum Destoner– Gravity Selector Cum Destoner is used to remove stones from the material. This machine is used in milling plants for removing stones and other impurities for food grains and pulses. Our offered machine is manufactured using basic components and ultra-modern techniques in adherence to set industry standards. We have used latest technology and trained engineers to developed the machines.

Reel Machine– To remove the various impurities. Also used for grading purpose. We are manufacturing machine with latest and sophisticated technology. This is a sieve separator widely supplied to flour and dall milling industry. Used for pre-cleaning and grading and separating jute twine cutting rugs, the Reel Machine separates out big size materials like chalk, husk and stones through sieve. Our machines can be available by customers in different capacities at cost effective price.

Intensive Dampeners– With several years of knowledge in this field, we are engaged in offering a quality-assured array of Intensive Dampeners. The provided dampeners are used to control the water in the process of cleaning wheat and corn. It is also used to improve the functioning of grinding, screening as well as the productivity. The offered dampeners are manufactured at our well-equipped premises with the use of superior quality components as per international quality standards. Our clients can avail these Intensive Dampeners at reasonable prices from us.

Water Flow Meter– Owing to our advanced infrastructural facilities in this domain, we are able to provide pristine quality Water Flow Meter. The offered meter is manufactured with the use of optimum grade components and is made available in different technical specifications. This meter is intended for measuring flow of electrically conductive liquids in closed pipe lines. Additionally, the provided Water Flow Meter can be availed from us at market leading prices by our respected clients.

Aspiration Channel– Being a leading firm in this industry, we are engaged in offering a high quality range of Aspiration Channel. The provided channel is manufactured using optimum quality components as per set quality standards with the aid of ultra-modern techniques by our ingenious professionals. This channel is widely used in grain cleaning applications for separating lighter particles from granular products. Apart from this, our clients can avail the offered Aspiration Channel at competitive prices from us.

Re Circulating(Dal) Dryer– This machine is used to reduce the moisture from the pulse.Our hot air genrating system is designed specifically for mass Industrial auto drying of pulses. It’s superior design, efficient performance and high fuel economy makes it a better buy than any other heater-drier of its kind to achieve much lower drying costs. The unit is easy to install, simple to maintain and highly economical to operate.

Pneumatic Silogate– This machine is used to control the flow of material. Pneumatic Silogate are designed to direct product flow outlets of storage bins, silo conveyors, gravity flow chutes .We have developed the machine with best technology and trained engineers.

Centrifugal Fan– We are an outstanding entity, betrothed in manufacturing, exporting and supplying top grade Centrifugal Fan. This fan is manufactured by a team of our skilled professionals using supreme quality components at our sophisticated premises. Finding its application in various industries, the provided fan is widely used for moving air or other gases. Apart from this, the offered Centrifugal Fan can be bought by our valued patrons at market leading prices from us.

Cyclone– Being a customer oriented organization, we are deeply engaged in manufacturing, exporting and supplying a wide array of Industrial Cyclone. This cyclone is manufactured using optimum quality components by dedicated professionals at our modern premises. The provided cyclone is used in kitchen ventilation for separating the grease from the exhausted air in extraction hoods. In addition to this, the offered Industrial Cyclone can be bought from us at competitive prices.

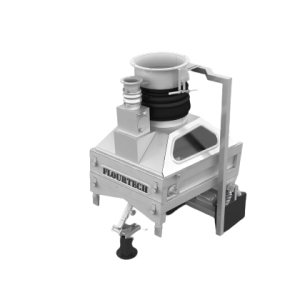

Bin Discharger– It is fixed below the Bin to discharge the material from it. Individually engineered for each application, the unique design of Bin Discharger allows easy installation with the ruggedness to stay on-line. The Bin Discharger’s simple, compact design incorporates all of the important features customers have come to expect a leak proof molded sleeve, heavy duty suspension system and long life vibrator.

Airlock– We are a trusted organization, successfully engaged in manufacturing, exporting and supplying superior grade Industrial Airlock. This airlock is manufactured under the guidance of our adroit professionals using optimum quality components with the aid of progressive techniques. The provided airlock is used to control the flow of discharged material from a dust collector by maintaining an air seal. Apart from this, the offered Industrial Airlock can be bought from us at marginal prices.